HANNOVER, Germany–For many years, Agritechnica has been growing and strengthening its role as the top European agricultural trade show. Despite the struggles that the industry is facing, with declining order books and a less than enthusiastic outlook for 2020, Agritechnica 2019 held here Nov. 11-16, 2019, reaffirmed its position as the most important ag tech event in Europe. The show reported 2,820 exhibitors and 450,000 visitors, more than 130,000 of them from outside Germany.

OEMs and component suppliers brought many innovations, with sustainability and efficiency as key factors in the development of the industry. It is no a surprise that the focus of the show was on electrification and automation. While the former is still far from being a practical solution for the entire ag industry, the latter has consolidated as essence of farming and it’s rapidly evolving in more autonomous vehicles.

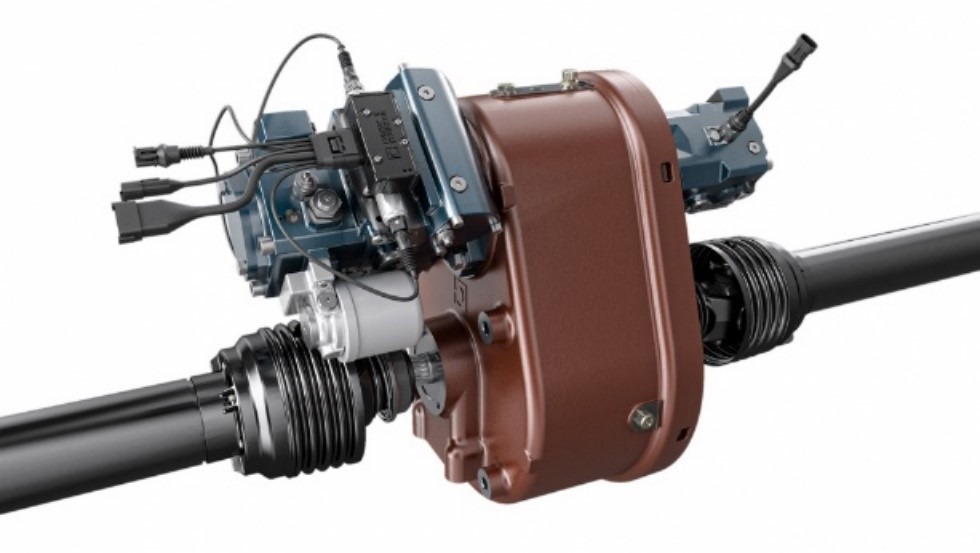

BONDIOLI & PAVESI introduced their new Continuously Variable Transmission Unit (CVT). The proposed transmission won the award Systems & Components Engineers’ Choice Trophy organised by DLG (German Agricultural Society). The CVT splits the machine’s drive shaft between the tractor’s power take-off (PTO) and the machine, and can be used for any applications where the speed of the implement needs to be continuously varied to match different working conditions – while the speed of the tractor PTO remains constant.

One of the benefits claimed by the company is an increased productivity of the machinery. The CVT unit can adapt the speed according to the task required by the implements, independently from the engine speed. The high efficiency and the increased performances allow for lesser fuel consumption. The unit is coupled with an electronic control unit made by Bondioli & Pavesi, that monitors the CVT functions.

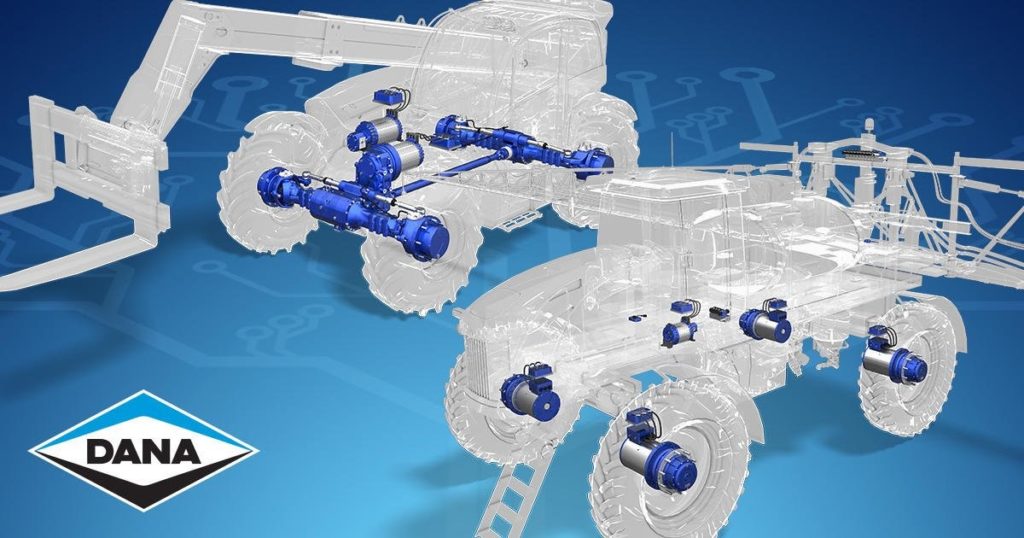

Dana Incorporated brought many innovations on their stand and in many products showcased around the fair. The Spicer® 980 independent suspended axle is featured on the Fendt 942 Vario tractor, the winner in the premier “Tractor of the Year” category. Dana also supplies the front axle for the Fendt 314 Vario Profi+, which topped the “Best Utility” classification.

Additionally, high-precision gears and shifting solutions from Dana are used in the transmissions of the New Holland T 4.110 N, which was named “Best Specialized” tractor, and the New Holland Methane Power Tractor, which was honored as the “Sustainable Tractor of the Year.”

Dana is also showcasing drive systems for telehandlers and field sprayers to illustrate the company’s modular approach for seamlessly packaging hybrid and electric drivetrain solutions into current internal combustion vehicle architectures. The system comprises Spicer® Electrified™ e-Axles and e-Gearbox that in combination with Dana’s Spicer® Smart Suite™ Intelligent Load Monitoring System (ILMS) allow to increase safety and productivity.

Dana technology also was showed at the Trelleborg stand. The tire manufacturer introduced several products and concepts. Together with Dana they developed a prototype of the Central Tire Inflation (CTIS) system for the agricultural machinery industry. Named CTIS+ Inside, the full OEM integrated central pressure control system enables tractor drivers to inflate or deflate tire pressures directly from the tractor cabin, according to the recommended pressure calculated by the advanced Trelleborg Load Calculator (TLC) software.

According to Paolo Pompei, President of Trelleborg Wheel Systems, “the adoption of the correct inflation pressure can cut farming variable costs by as much as 20%, while reducing the environmental footprint of farming operations.”

Trelleborg and Dana plan to have the systems available to OEM and aftersales operations by end of 2020. The system will be compatible with axles and hubs of other manufactures as well.

Looking forward, Trelleborg has also launched PneuTrac, a hybrid variation between a conventional tire and a rubber track. New Holland has selected the new tire for its specialized range of vineyard tractors.

PneuTrac contains the best-in-class features of Trelleborg agricultural tires along with a sidewall adopting the CupWheel Technology by Galileo Wheel Ltd. The innovative “Omega” design of the sidewall helps the carcass to sustain load, simultaneously providing flexibility and an extra-wide footprint, resulting in very low soil compaction. This design allows the tread to work at 100% of its potential efficiency.

Moving to the engine compartment, suppliers showcased several interesting solutions. FPT, a brand of CNH Industrial, introduced a hybrid concept together with tractor manufacturer Steyr (another brand of CNH Industrial).

The new concept features innovative architecture, with a serial hybrid approach where the diesel engine, a compact 4.5-liter 4-cylinder unit, instead of the 6-cylinder traditionally installed on such a tractor range, works at optimal speed as an energy generator, charging batteries. The engine is disconnected from the wheels, and traction is provided by four independent electric motors directly installed in the wheel hubs.

The STEYR Konzept is equipped with a NEF45 engine, which delivers 150 kW peak power, while 250 kW peak power in hybrid boosting mode is guaranteed. The concept can reach 10% fuel saving compared with pure Diesel on some specific tractor missions.

Traditional tractor operation is ensured by electrically driven hydraulic systems and a mechanical PTO; an additional motor can be added to drive electrical implements for higher precision operation.

The battery pack is modular, a key feature to guarantee the appropriate pure-electric autonomy range in all missions; this will also play a central role in future electrification projects.

Besides the prototype, FPT also introduced several engines. Among them, the N67 Natural Gas engine is designed to offer diesel-like performance with reduced emissions. Compatible with Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG) and biomethane, the N67 NG has 10% lower CO2 emissions than Diesel engines in real field conditions. When running on biomethane, this can reach virtually zero or even become negative, contributing to a new circular economy free from waste and fuel costs, that can lead to much more efficient and productive agriculture, according to FPT.

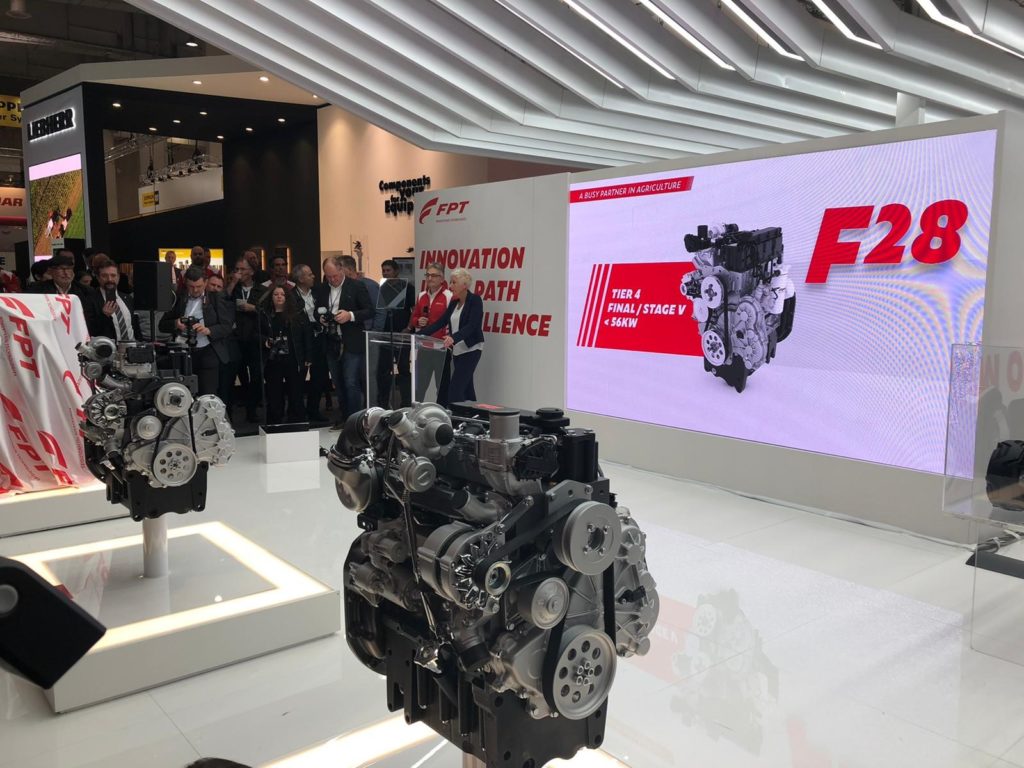

Another engine introduced at Agritechnica was the F28. It delivers maximum power of 55 kW at 2,300 rpm and maximum torque of 375 Nm at 1,400 rpm. Compliant with Stage V and Tier 4 Final emission standards, F28 takes advantage of FPT’s ultra compact after-treatment solution, which uses a Diesel Oxidation Catalyst (DOC) + Diesel Particulate Filter (DPF) for the European market, and a DOC for North America, maintaning the same packaging for both regions.

Following its strategy of offering multi-power solutions, FPT Industrial is offering a 100% Natural Gas version of F28, with the same displacement and interface as the Diesel version, using common base components, and a 3-way catalyst as the after-treatment system. The F28 NG will further reduce pollutant emissions to enable even more sustainable agriculture

Agritechnica closed its doors with impressive attendance numbers. More than 450,000 visitors and 2,820 exhibitors join the event. While international visitors rose to 130,000 (+18% vs 2017) the overall figures are down slightly compared to the previous edition (-2% in total visitors). This is in line with the general feeling of the market.

2020 expectation for machinery sales is flat to slightly negative compared to 2019. And yet another confirmation of the current state of the Ag industry comes from the exhibitor and visitor surveys organized by DLG.

% of exhibitors reported a positive overall result of their participation at the end of the Exhibition

% of exhibitors rated the after-sales prospects for the fair as positive

Are investments planned in the next two years?

These trends are reported in our machinery production forecast database, OE Link™. If you need more information about the agriculture industry, or any other power product segment, please contact us; we’ll be happy to assist you with your market intelligence needs.

Electrification Hybrid technology

Although not every application is suited to early electrical adoption, such as larger tractors and combines, Electrification is a hot topic for the Agricultural sector. Hybrid options seem to be slightly favored when it comes to internal combustion alternatives for mid-sized applications.

Powertrac demonstrated this option at Agritechnica 2019 with their new hybrid tractor concept. Steyr, the premium agricultural brand of CNH partnered with FPT Industrial to create the “Steyr Konzept” centered around a modular hybrid electric drive, comprising a highly efficient diesel engine, a generator and five electric motors.

For smaller applications, fully electric options are more commonly used. As we already know, many key players have already entered the electric game, and we now see a couple more joining in. Tobroco-Giant introducing its first electric wheel loader in the 2.2 ton class, the G2200E. With two separate electric motors, 6.5kW to drive the machine and 11.5kW for the hydraulics, there is always enough power. Furthermore, the machine regenerates energy when it rolls out or drives downhill.

JCB has also unveiled its new electric telescoping loader, the Teletruk 30-19E. Capable of 8 hours work on one charge, and, since the arm is mounted laterally instead of the more common vertical, it gives this unique loader a significant increase in capacity.

New models and technology

With the introduction of Stage V for off-road applications between 56 to 130 kW next year, we have seen a number of revamped models to accommodate the new Stage V engines. Since this has already been done for other models outside of this range at the start of this year, the transition is pretty smooth. We also had a chance to see the X9 twin rotor combine by John Deere designed to be the widest body combine on the market, while staying within EU directives. We will have to wait until July to get the final details.

Staying with John Deere, they have introduced an alternative to hydrostatic drives; they have basically replaced the hydraulic part of the engine with electricity. It is still in early in the product life cycle to determine exactly what the implication of this product can have, but it could have big implications.

Finally, John Deere has teamed up with Volocopter, the Germany start-up company, to develop a drone for pulverization as an alternative to helicopter pulverization. The drone can perform this task much more efficiently with less spread and could be very useful in fields close to habitations.

Autonomous Concept Vehicles have made their way into the 2019 Agritechnica. Case brought their autonomous tractor and John Deere brought their autonomous sprayer. These are still in the early stages, but it is good to see, in this current climate, OEMs are opening up to many different solutions for the future. PSR